STANDARD: EN 12697-35 | ASTM D6307 | AASHTO TP53

The PaveMix has been expressly designed to prepare homogeneous bituminous mixtures at a strictly controlled temperature.

The preparation of the bituminous sample is obtained in a short time period (few minutes) to avoid any mechanical aggregate degradation and to

fully coat all mineral components, as requested by EN 12697-35.

B026-05N

PAVEMIX

LABORATORY MIXER similar to model B026N but upgraded with detachable helical mixing blades to facilitate the cleaning procedure.

MAIN FEATURES

Mixing capacity: 32 litres max.

Mixing bowl: stainless steel AISI 316.

Mixing temperature: selectable from ambient up to

260 °C through sensitive probe and digital display

control.

Mixing speed: adjustable from 4 to 40 rpm.

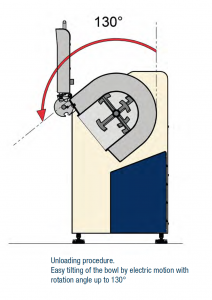

Easy tilting unloading operation by

electromechanical motion with rotation up to 130°.

Strictly controlled temperature.

Fast preparation of bituminous samples.

The Pavemix produces representative samples to perform:

– Gyratory compaction tests (EN 12697-10, EN 12697-31)

– Marshall stability tests (EN 12697-34, EN 13108)

– Wheel tracking wet and dry tests (EN 12697-22)

– Slabs compaction laboratory tests (EN 12697-33)

– Beam fatigue and Stiffness tests (EN 12697-26, EN 13108)

– Asphalt general purpose tests.

PaveMix consists of:

– Main frame holding a horizontal stainless steel bowl with a helical

mixing shaft.

– The bowl, double wall insulation made of stainless steel AISI 316,

contains an electric heater with probe sensor granting constant

and uniform temperature control.

– An electromechanical motion allows to tilt the bowl facilitate

the unloading operation, with total rotation up to 130°.

The control panel foresees:

– Digital thermo regulator to set temperature and to control the

mixing temperature.

– Mixing speed regulator.

– Main and start/stop switches.

– Command to tilt the bowl.

Heating power: 3000W

Power supply: 230V 1ph 50-60Hz 4500W

Dimensions: 1280x700x1210 mm

Weight: 350 kg approx.